RPM Sync

You can watch the video tutorial on how to make RPM synchronization

Preparation

The RPM synchronization procedure is performed to automatically calculate the total Gear Ratio between the vehicle engine and the roller or flywheel where the system rotation sensor is mounted.

DIRECT TRANSMISSION

The synchronization procedure is carried out on roller test benches or on motor test benches that have an indirect transmission. In the case of engine test benches with direct transmission between crankshaft and dynamometer it is not necessary to carry out this procedure and the transmission ratio must be left with the value *1.0*.

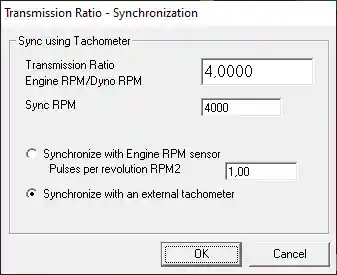

This gear ratio value is required for the software to display the RPM of the motor, rather than the RPM of the roller or flywheel. For example, if the motor at 6,000 RPM produces a roll rotation of 1,250 RPM, the gear ratio would be 4.8 (6,000/1,250).

TRANSMISSION RATIO

If you have previously tested this vehicle, it will be possible to enter the transmission ratio manually in the OptionsTransmission Ratio menu without the need of synchronizing it.

The gear ratio is easily calculated using the vehicle's tachometer, or if you don't have one, by mounting an external tachometer on the vehicle.

Sync

To sync RPM press the S key on the keyboard at the gear you will later use it to make the power test.

You can also synchronize the RPM using the system push button, previously pressing F12 key to enter RPM sync mode.

Results

RPM ON DISPLAY

Keep in mind that if the vehicle has not been synchronized yet, the engine RPM displayed on the screen will not be correct. Only after having done the synchronization the correct value will be displayed.

In the OptionsGear Ratio menu you can change the RPM at which the synchronization is performed. We recommend working with a rather high value to reduce the margin of error. It is also convenient to synchronize at an RPM value where you are going to work with the engine, for example to do the mapping at 5000 RPM, it is convenient to synchronize at 5000 RPM.

VARIABLE RATIO

In roller dynos the gear ratio varies slightly with speed. This is because the ratio is given by the diameter of the wheels and that diameter varies as speed increases as the wheels spin and the effective diameter increases due to centrifugal forces.

AUTOMATIC GEARBOX

In the case of automatic gearboxes, synchronization should be carried out at high RPM, or using the RPM cutoff to synchronize. Note that the RPM displayed on the screen may not match the actual RPM of the engine. In that case you can work with the Power versus Speed graphs and not with Power versus RPM.

Once the RPM is synchronized, we should notice that the RPM on the screen is similar to the RPM read on the vehicle's tachometer. If this is OK, we can now remove the external tachometer and continue working with only the on screen tachometer.

SYNCHRONIZATION ERRORS

It is not critical that the RPM value has a small difference. This does not affect the power measurement at all, it will just cause the curve to appear shifted on the graph by the same value as the RPM error.