RPM1 (roller/flywheel)

Sensor Mount

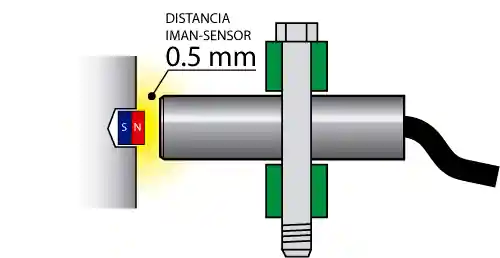

The RPM sensor should be mounted rigid, without any type of rubber or cushioning. It is recommended to use a metal or plastic clamp to fix it at a distance of 0.5mm to 1mm from the north pole of the magnet.

Magnet Installation

The magnet must be mounted on the flywheel or side of the roller, preferably away from the axis, although it also works on the axis.

WARNING

The north pole of the magnet must be in the direction of the rotation sensor.

To mount the magnet, use a 2-component epoxy-type adhesive. It is recommended to mount the magnet into a shallow hole on the flywheel or roller.

In the event that the assembly is carried out on a ferromagnetic material such as iron or steel, it is recommended that the magnet is not embedded in the hole, but should protrude approximately 0.5mm. This is to prevent the iron from absorbing the magnetic field lines, which would cause the need to mount the sensor closer to the magnet.

TEST

You can use the interface to test the sensor and the correct mounting of the magnet.

- Software must not be open.

- Connect the USB port of the Accudyno interface to the PC.

- Also connect the rotation sensor to the RPM1 input.

- Move the sensor closer to the magnet. You will see the red light on the interface change state from flashing to steady on.

- When removing the magnet, the light will turn off.

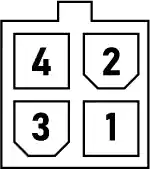

RPM1 Input Pinout

| Number | Function | Range | No. Signal in Software |

|---|---|---|---|

| 1 | VDC | +5V for sensor | |

| 2 | GND | 0V | |

| 3 | Signal | Digital input with 2K pullup | 10 |

| 4 | N/C | No Connection | - |

Pulses per revolution: software programmable.

Provided Sensor Specifications

| Type | Hall Effect Sensor |

|---|---|

| Supply Voltage | 5V Nominal / 24V max |

| Magnetic Polarity | Active by north pole (unipolar only) |

| Output Type | Open Collector |

| Working distance | With neodymium magnet ~1 mm |

| Diameter | 15.9mm |

| Length | 80mm |

| Cable length | 3.5m |

| Magnet | Neodymium. Diameter 5 or 6mm. Thickness 2.5mm |